Welcome to 3F: Revolutionizing 3D Printing with Advanced Technology

After two decades of innovation in advanced composite materials, high-performance fibers, and industrial textiles, 3F is proud to introduce a groundbreaking development in the world of 3D printing: 3FyL™ Filament Technology.

What is 3FyL™?

3FyL™ is more than just a new material—it’s an entirely new class of filament technology. Combining cutting-edge polymer science, high-performance fiber spinning, and advanced composite materials, 3FyL™ is designed to take your 3D printing experience to the next level. This high-performance filament is compatible with Fused Filament Fabrication (FFF) 3D printers, offering unmatched durability and strength.

Technology Backed by Research and Innovation

The 3FyL™ Filament Technology is the result of years of dedicated research and development, including NSF-funded projects and collaborative efforts with the U.S. Army. This innovative filament incorporates patent-pending technology, ensuring that you get the highest quality performance.

What Makes 3FyL™ Unique?

- Self-Reinforced Strength: 3FyL™ filaments are self-reinforced with continuous fibrils of ultra-high-performance Thermoplastic Liquid Crystal Polymer (TLCP). These fibrils, as small as 0.5 microns in diameter, are co-extruded with a matrix polymer like PETG, Polycarbonate, or Nylon to create a unique composite material.

- No Wear on Nozzles: Unlike traditional filaments, 3FyL™ is wholly thermoplastic, meaning it contains no carbon or glass fibers that can wear out your 3D printer nozzle.

- Compatible with Open-System Printers: 3FyL™ filaments work seamlessly with all open-system desktop and larger 3D printers.

With 3FyL™, you’re not just printing objects; you’re advancing the potential of 3D printing itself. Explore the future of high-performance materials today.

Discover the 3FyL™ Difference

Summary of 3FyL™ Filament:

3FyL™ Filament is a self-reinforced thermoplastic polymer designed for Fused Filament Fabrication (FFF) 3D printing. This innovative material enables the creation of parts as strong as metals, suitable for both low-cost desktop printers and large industrial systems. It provides an analogy to printing Kevlar®-reinforced Lexan® on printers ranging from $1,500 desktop models to $250,000 industrial-grade machines. The filament has a virtually unlimited shelf life, does not require special storage, and involves no hazardous materials, making it safe and easy to handle.

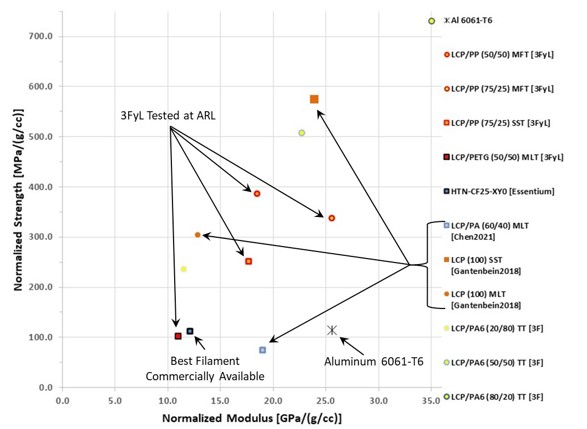

3FyL was developed by 3F with funding for commercial and industrial applications, and its launch is expected in 2025. The filament will be tested and demonstrated for its mechanical properties—strength, stiffness, and toughness—through both material and printing parameter optimization. This filament is designed to be printer-agnostic, working with most FDM/FFF systems, and is stronger, stiffer, and less dense than aluminum and carbon fiber composites, while remaining highly tough due to its thermoplastic nature.

3FyL has significant potential for commercial and military use, including rapid prototyping and production, battlefield manufacturing, and repair/replacement of parts. Its advantages extend across various scales of FFF printing, from small desktop units to large AM systems for parts of substantial size. In the defense sector, it can reduce costs and complexities in operational readiness and provide innovative solutions in real-time. Additionally, the filament’s broad applicability makes it a versatile material for everything from R&D to field use by military personnel.

Ultimately, 3FyL™ materials promise more lethal systems, increased material readiness, and enhanced capabilities for Warfighters, all while being safe, versatile, and cost-effective.

Opportunity

- Ubiquitous FFF/FDM Printers =>Now => Industrial Performance

- Low-Cost/Desktop 3D Printer Revolution

Bambu Lab Phenomenon (Chinese) =>Market-altering over last ~2 yrs

Less $ and more capability

Solution

- Proprietary Nano-Engineered Co-Extrusion

- Continuous-Fibril-Reinforced, Liquid Crystal Polymer (TLCP), Advanced Composites

- ‘Prepreg in a Filament™’ for your printer

- Exceptional Strength, Stiffness AND Toughness

- One Filament – Tailored Material Properties

- Design both geometry AND material

- Control properties via printer parameters

- Desktop printer or 6-Axis robot = Automated Mfg

- Derived from NSF, 3F IRAD, & US Army (ARL) Technology & Funding | TRL 6 & MRL 6

Problem

- Materials Limited – large # of cosmetic choices but low mechanical properties

- Design Limited – one material at a time

- Application Limited – non-loadbearing

Impact

- Radically Enhanced AM Design Window

- Less material = shorter prints AND more performance

- Multi-functional structures, redundant and/or distributed load paths

Safer & Easier AM Mfg at Point-of-Need

Unlike AM powders & liquid resins, 3FyL =>non-hazardous/explosive, indefinite shelf-life - Wide Range of Applications

- Drones that carry more, fly farther, tolerate greater battle damage

- Repair & replace structural parts

- Longer lasting jigs, fixtures, tooling

Innovate anywhere – R&D lab, battlefield, =>repair depots, production floor, …